Practices › Speciality Chemicals › Colorants Market

Colorants Market

The colorants market is projected to reach USD 65.65 billion by 2022, at a CAGR of 5.0% from 2017 to 2022. The colorants market has witnessed high growth in the recent years, and this growth is projected to continue in the near future, owing to the increase in demand for colorants in various end-use industries, such as packaging, building & construction, and automotive, among others and in applications such as plastics and paints & coatings. The growing demand for plastics in various industries is also a driver for the growth of the colorants market.

On the basis of type, the colorants market has been segmented into pigments, dyes, masterbatches and color concentrates. The pigments segment leads the colorants market. The growth of this segment of the market can be attributed to the increasing use of pigments in the paints & coatings application in the automotive and building & construction industries. The market for masterbatches is projected to grow at the highest CAGR during the forecast period due to the growing plastics industry.

On the basis of end-use industry, the colorants market has been classified into packaging, textiles, paper & printing, building & construction, automotive, and others. The packaging end-use industry is leading the colorants market and is projected to grow at the highest CAGR during the forecast period. The growth of the packaging end-use industry in the colorants market is due to the increased demand for colorants for coloring plastics used for lightweight packaging. Moreover, increasing use of colorants to color packaging materials such as plastics, paper, metal, fabric, and so on has also propelled growth in this industry.

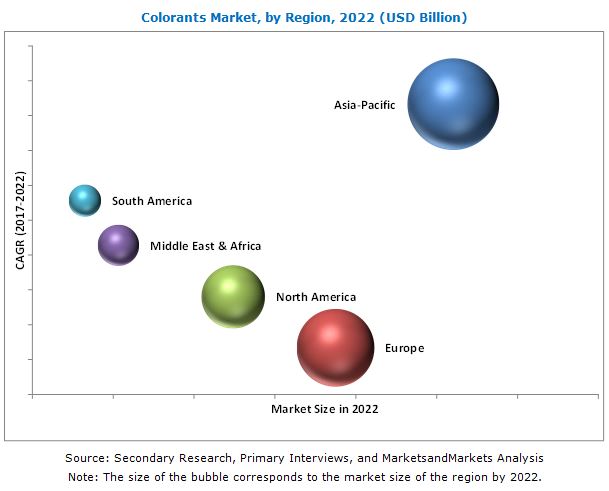

Based on region, the colorants market has been segmented into Asia-Pacific, North America, Europe, the Middle East & Africa, and South America. The Asia-Pacific colorants market is projected to grow at the highest CAGR during the forecast period, owing to the increasing demand for colorants in packaging medical, pharmaceutical, and food & beverages products.

Packaging

Packaging protects goods during distribution, transportation, storage, and use. The aesthetic appeal of a package is extremely important to attract the consumer. Color helps in distinguishing product and establish brand identity. Hence, colorants play an important role in making packaging attractive.

The packaging end-use industry uses different materials such as plastics, metal, and fabrics. Different types of colorants are used depending on the types of materials that must be colored. Dyes are used in inks to print on various packaging materials such as paper, cardboard plastics, and metal. They are also used to manufacture packaging printing colors for paperboard containers, bags, sacks, flexible packaging, boxes, and tubes. Pigments are helpful in giving effects to various packaging products. There are various pigments of food and non-food grades which are used in packaging depending on the applications. For instance, for packaging of food products, cosmetics, medical & pharmaceutical food grade pigments are preferred while non-food grade pigments are preferred in sports equipment, packaging of electronic goods, and other applications. Color concentrates are widely used in plastic packaging for food, cosmetic, and consumer products. Color concentrates and masterbatches with different dosing ratios give a variety of color shades. These color shades make packaging colorful and enhance the consumer appeal of the goods. Colorants are widely used in rigid and flexible packaging applications such as food packaging, bottles, PET, oil, pharmaceutical, and chemical in various forms such as caps, bottles, trays, bags, and pouches.

Textiles

The textile industry has a high consumption of colorants. Applications of colorant types such as dyes and pigments in the textile end-use industry are also undergoing changes to meet the rapidly changing demand from the fashion industry. For instance, disperse polyesters mainly consume dyes. Similarly, color concentrates are used in coloring plastic material used in carpets, curtains, cushion covers, disposable medical garments such as masks, gloves, and other breathable fabrics. Cotton fabrics are more in demand during the summers, which increases the demand for vat, reactive, and direct dyes. Moreover, growing demand for environmentally friendly products propel the sales of dyes for textile applications. Colorants are used in textiles for two reasons mainly, to color the fabric entirely and to print the desired pattern on fabric or textile materials.

Automotive

The automotive end-use industry requires high color control and advanced technologies to produce colorants suitable for outdoor applications where the automotive is subjected to UV exposure. Various types of colorants are used in different applications in the automotive end-use industry. Water soluble and oil soluble dyes are widely used in various automotive applications such as automotive fabric, components, window washer fluid, industrial engine cleaners, soaps for car washes, and for coolants. High-performance pigment dispersions are used in various automotive applications such as exterior finishes, interior stylings, and functional coatings. Similarly, the metal effect and pearlescent pigments are used in giving an elegant appearance to the automotive. Color concentrates find use in lighting systems, cooling system, engine covers, electrical & electronic sensors, front-end modules, air-intakes, batteries, and so on in the interior of automotive where plastic is used. Similarly, exterior parts of the automotive such as wheel trim, rub strips, grills, sealing systems, as well as large parts such as fenders, bumpers, spoilers, and so on use color concentrates. Color masterbatches are used in door panels, headliners, floor coverings, seat upholstery, side view mirrors, running boards, interior & exterior trim, and so on.

The key restraining factors for the colorants market are environmental regulations and volatility in raw material prices. This is expected to trigger innovations in the colorants market, as manufacturers of colorants are expected to take initiatives to manufacture colorants that are compliant with regulations. Moreover, companies such as, Clariant AG (Switzerland), BASF SE (Germany), DIC Corporation (Japan), Huntsman Corporation (U.S.), E. I. du Pont de Nemours & Company (U.S.), Cabot Corporation (U.S.), LANXESS AG (Germany), PolyOne Corporation (U.S.), and Sun Chemical Corporation (U.S.) are investing in R&D activities to launch new products and strengthen their positions in the colorants market.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst