Practices › Fibers & Composites › Closed Molding Composites Market

Closed Molding Composites Market

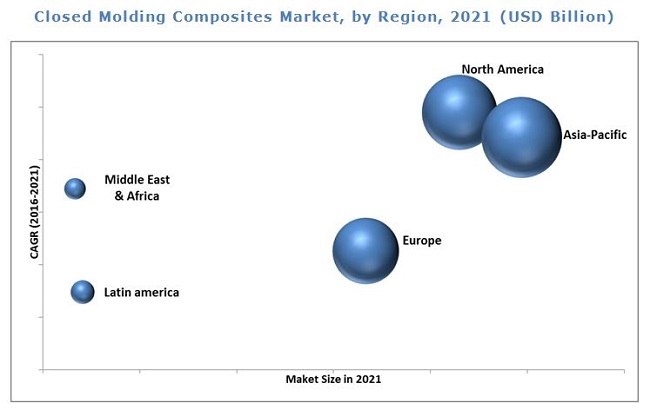

The global closed molding composites market is projected to grow from USD 46.48 Billion in 2016 to USD 66.58 Billion by 2021, at a CAGR of 7.45% during the forecast period. The closed molding composites market is growing because high demand from the aerospace & defense industry, as they have the ability to reduce weight and increase fuel efficiency. Closed molding process improves productivity through innovative engineering approaches, minimizes energy consumption, and reduces VOC emission level. The market witnessed a strong growth in the past few years considering the use of composites in the U.S., Germany, and developing countries such as China, Brazil, and Japan.

The closed molding composites market is segmented on the basis of manufacturing process into vacuum infusion & bagging, compression molding, pultrusion, injection molding, RTM, and others. Vacuum infusion & bagging is the most preferred closed molding process to manufacture composites that accounted for a major share, in terms of value, in 2015. This is because of its use in manufacturing components for aerospace & defense, transportation, and wind energy applications. The process produces strong, lightweight laminates, and offers substantial emission reductions. The demand for closed molding composites manufactured by compression molding process is increasing in applications such as transportation, construction, and electrical & electronics, as they require good surface finish and non-corrosive properties, which are provided by these composites.

The closed molding composites market in aerospace interior is also segmented by application, which includes transportation, aerospace & defense, wind energy, electrical & electronics, construction, and others. Aerospace & defense accounts for the highest market share in terms of value owing to the factors such as rise in monthly production of Boeing’s 787 from 10 aircraft to 12 aircraft in 2016 (Composites World); it is expected to reach 16 aircraft per month by 2019. This is likely to increase the demand for closed molding composites from Boeing, as they account for nearly 50% of the structural components of Boeing aircraft.

Currently, Asia-Pacific is the largest consumer of closed molding composites. Japan and China are also the major markets due to the growing wind energy industry in China, which witnessed the highest number of wind energy installations in 2015. This increases the RTM process, as it is mainly involved in manufacturing closed molding composites for this industry.

High cost of raw materials and high investment costs restrain the growth of the closed molding composites market.

Royal TenCate N.V (Netherlands), Core Molding Technologies Inc. (U.S) and Strongwell Corp. (U.S) are some of the leading players in the closed molding composites market. Royal TenCate N.V has been able to hold a leading position in the market by tapping various global markets. It has undertaken strategic alliances with local distribution centers of emerging markets to increase its market share and customer base. As a part of the closed molding composites company growth strategy, it is mainly focused on agreements and partnership strategies.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst